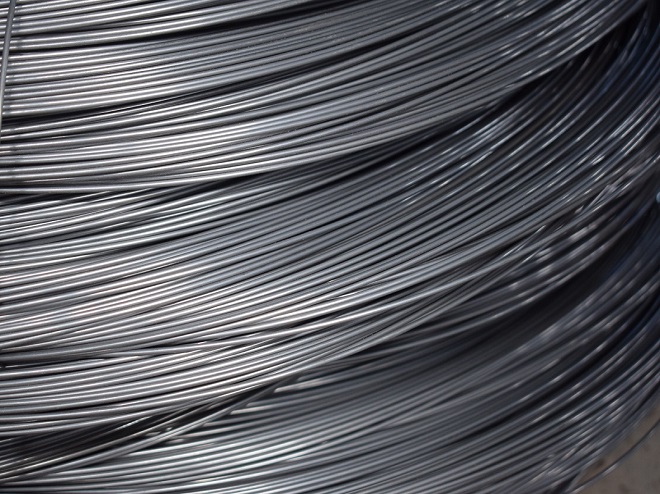

Cold Drawn Steel Wire

Diameter Range:0.15mm-12.0mm

Raw Material:45#, 60#, 65#, 70#, 72A, 72B, 82A, 82B, 65Mn

Application: mechanical spring, compression spring, extension spring, torsion spring, mattress spring.

Piano Wire/Music Wire

Diameter Range: 0.15mm-6.0mm

Raw Material: 82A, 82B, 65Mn

Application: mechanical spring, compression spring, extension spring.

Shaped/Flat Wire

Dimension Range: thickness 1.0-5.0mm, width 2.0-15.0mm

Raw Material: 65Mn、60Si2Mn,72A, 72B, 82B, 55SiCr

Application: seat adjuster spring, window regulator spring, wave spring, wiper, retaining ring.

| Grade | C1 | Si | Mn2, 3 |

P max. |

S max. |

Cu max. |

|||

| SL | 0,35-1,00 | 0,10-0,30 | 0,40-1,20 | 0,035 | 0,035 | 0,20 | |||

| SM | 0,35-1,00 | 0,10-0,30 | 0,40-1,20 | 0,035 | 0,035 | 0,20 | |||

| SH | 0,35-1,00 | 0,10-0,30 | 0,40-1,20 | 0,035 | 0,035 | 0,20 | |||

| DM | 0,45-1,00 | 0,10-0,30 | 0,40-1,20 | 0,020 | 0,025 | 0,12 | |||

| DH | 0,45-1,00 | 0,10-0,30 | 0,40-1,20 | 0,020 | 0,025 | 0,12 | |||

| 1. Such a wide range is stipulated to accommodate the whole range of sizes. For individual sizes the carbon range is substantially more restricted; 2. The range of manganese content in the table is wide to cope with various processing situations and the broad size range. The actual figures per size shall be more restrited; 3. For the manganese content, a different range from the one indicated in the table may be agreed at the time of ordering, with a maximum not exceeding 1,20% and with a minimum range of 0,20%. |

|||||||||

| Grades | European Standard | DIN |

US ASTM |

JAPAN JIS G-3506/G3522 | CHINA GB/T 4357 | ||||

| SL | EN 10270-1 | KLASSE A | A 227 | SWB | SL | ||||

| SM | EN 10270-1 | KLASSE B | A 227 | SWC | SM | ||||

| SH | EN 10270-1 | KLASSE C | A 228 | SWP-B | SH | ||||

| DM | EN 10270-1 | - | A 227 | - | - | ||||

| DH | EN 10270-1 | KLASSE D | A 228 | SWP-B | DH | ||||

|

Tensile Strength1 |

Static |

Dynamic |

|

Low |

SL |

- |

|

Medium |

SM |

DM |

|

High |

SH |

DH |

| 1. For other tensile strength may be agreed. | ||

Tensile Strength Rm

|

Nominal Diameter mm |

SL MPa |

SM MPa |

DM MPa |

SH MPa |

DH MPa |

Minimum area reduction after Z break % |

|||

| d=0,2 | - | - | - | - | 2800 - 3110 | - | |||

| 0,20 < d ≤ 0,22 | - | - | - | - | 2770 - 3080 | - | |||

| 0,22 < d ≤ 0,25 | - | - | - | - | 2720 - 3010 | - | |||

| 0,25 < d ≤ 0,28 | - | - | - | - | 2680 - 2970 | - | |||

| 0,28 < d ≤ 0,30 | - | 2370 - 2650 | 2370 - 2650 | 2660 - 2940 | 2660 - 2940 | - | |||

| 0,30 < d ≤ 0,32 | - | 2350 - 2630 | 2350 - 2630 | 2640 - 2920 | 2640 - 2920 | - | |||

| 0,32 < d ≤ 0,34 | - | 2330 - 2600 | 2330 - 2600 | 2610 - 2890 | 2610 - 2890 | - | |||

| 0,34 < d ≤ 0,36 | - | 2310 - 2580 | 2310 - 2580 | 2590 - 2870 | 2590 - 2870 | - | |||

| 0,36 < d ≤ 0,38 | - | 2290 - 2560 | 2290 - 2560 | 2570 - 2850 | 2570 - 2850 | - | |||

| 0,38 < d ≤ 0,40 | - | 2270 - 2550 | 2270 - 2550 | 2560 - 2830 | 2560 - 2830 | - | |||

| 0,40 < d ≤ 0,43 | - | 2250 - 2520 | 2250 - 2520 | 2530 - 2800 | 2530 - 2800 | - | |||

| 0,43 < d ≤ 0,45 | - | 2240 - 2500 | 2240 - 2500 | 2510 - 2780 | 2510 - 2780 | - | |||

| 0,45 < d ≤ 0,48 | - | 2220 - 2480 | 2220 - 2480 | 2490 - 2760 | 2490 - 2760 | - | |||

| 0,48 < d ≤ 0,50 | - | 2200 - 2470 | 2200 - 2470 | 2480 - 2740 | 2480 - 2740 | - | |||

| 0,50 < d ≤ 0,53 | - | 2180 - 2450 | 2180 - 2450 | 2460 - 2720 | 2460 - 2720 | - | |||

| 0,53 < d ≤ 0,56 | - | 2170 - 2430 | 2170 - 2430 | 2440 - 2700 | 2440 - 2700 | - | |||

| 0,56 < d ≤ 0,60 | - | 2140 - 2400 | 2140 - 2400 | 2410 - 2670 | 2410 - 2670 | - | |||

| 0,60 < d ≤ 0,63 | - | 2130 - 2380 | 2130 - 2380 | 2390 - 2650 | 2390 - 2650 | - | |||

| 0,63 < d ≤ 0,65 | - | 2120 - 2370 | 2120 - 2370 | 2380 - 2640 | 2380 - 2640 | - | |||

| 0,65 < d ≤ 0,70 | - | 2090 - 2350 | 2090 - 2350 | 2360 - 2610 | 2360 - 2610 | - | |||

| 0,70 < d ≤ 0,75 | - | 2070 - 2320 | 2070 - 2320 | 2330 - 2580 | 2330 - 2580 | - | |||

| 0,75 < d ≤ 0,80 | - | 2050 - 2300 | 2050 - 2300 | 2310 - 2560 | 2310 - 2560 | 40 | |||

| 0,80 < d ≤ 0,85 | - | 2030 - 2280 | 2030 - 2280 | 2290 - 2530 | 2290 - 2530 | 40 | |||

| 0,85 < d ≤ 0,90 | - | 2010 - 2260 | 2010 - 2260 | 2270 - 2510 | 2270 - 2510 | 40 | |||

| 0,90 < d ≤ 0,95 | - | 2000 - 2240 | 2000 - 2240 | 2250 - 2490 | 2250 - 2490 | 40 | |||

| 0,95 < d ≤ 1,00 | 1720 - 1970 | 1980 - 2220 | 1980 - 2220 | 2230 - 2470 | 2230 - 2470 | 40 | |||

| 1,00 < d ≤ 1,05 | 1710 - 1950 | 1960 - 2200 | 1960 - 2200 | 2210 - 2450 | 2210 - 2450 | 40 | |||

| 1,05 < d ≤ 1,10 | 1690 - 1940 | 1950 - 2190 | 1950 - 2190 | 2200 - 2430 | 2200 - 2430 | 40 | |||

| 1,10 < d ≤ 1,20 | 1670 - 1910 | 1920 - 2160 | 1920 - 2160 | 2170 - 2400 | 2170 - 2400 | 40 | |||

| 1,20 < d ≤ 1,25 | 1660 - 1900 | 1910 - 2140 | 1910 - 2140 | 2150 - 2380 | 2150 - 2380 | 40 | |||

| 1,25 < d ≤ 1,30 | 1640 - 1890 | 1900 - 2130 | 1900 - 2130 | 2140 - 2370 | 2140 - 2370 | 40 | |||

| 1,30 < d ≤ 1,40 | 1620 - 1860 | 1870 - 2100 | 1870 - 2100 | 2110 - 2340 | 2110 - 2340 | 40 | |||

| 1,40 < d ≤ 1,50 | 1600 - 1840 | 1850 - 2080 | 1850 - 2080 | 2090 - 2310 | 2090 - 2310 | 40 | |||

| 1,50 < d ≤ 1,60 | 1590 - 1820 | 1830 - 2050 | 1830 - 2050 | 2060 - 2290 | 2060 - 2290 | 40 | |||

| 1,60 < d ≤ 1,70 | 1570 - 1800 | 1810 - 2030 | 1810 - 2030 | 2040 - 2260 | 2040 - 2260 | 40 | |||

| 1,70 < d ≤ 1,80 | 1550 - 1780 | 1790 - 2010 | 1790 - 2010 | 2020 - 2240 | 2020 - 2240 | 40 | |||

| 1,80 < d ≤ 1,90 | 1540 - 1760 | 1770 - 1990 | 1770 - 1990 | 2000 - 2220 | 2000 - 2220 | 40 | |||

| 1,90 < d ≤ 2,00 | 1520 - 1750 | 1760 - 1970 | 1760 - 1970 | 1980 - 2200 | 1980 - 2200 | 40 | |||

| 2,00 < d ≤ 2,10 | 1510 - 1730 | 1740 - 1960 | 1740 - 1960 | 1970 - 2180 | 1970 - 2180 | 40 | |||

| 2,10 < d ≤ 2,25 | 1490 - 1710 | 1720 - 1930 | 1720 - 1930 | 1940 - 2150 | 1940 - 2150 | 40 | |||

| 2,25 < d ≤ 2,40 | 1470 - 1690 | 1700 - 1910 | 1700 - 1910 | 1920 - 2130 | 1920 - 2130 | 40 | |||

| 2,40 < d ≤ 2,50 | 1460 - 1680 | 1690 - 1890 | 1690 - 1890 | 1900 - 2110 | 1900 - 2110 | 40 | |||

| 2,50 < d ≤ 2,60 | 1450 - 1660 | 1670 - 1880 | 1670 - 1880 | 1890 - 2100 | 1890 - 2100 | 40 | |||

| 2,60 < d ≤ 2,80 | 1420 - 1640 | 1650 - 1850 | 1650 - 1850 | 1860 - 2070 | 1860 - 2070 | 40 | |||

| 2,80 < d ≤ 3,00 | 1410 - 1620 | 1630 - 1830 | 1630 - 1830 | 1840 - 2040 | 1840 - 2040 | 40 | |||

| 3,00 < d ≤ 3,20 | 1390 - 1600 | 1610 - 1810 | 1610 - 1810 | 1820 - 2020 | 1820 - 2020 | 40 | |||

| 3,20 < d ≤ 3,40 | 1370 - 1580 | 1590 - 1780 | 1590 - 1780 | 1790 - 1990 | 1790 - 1990 | 40 | |||

| 3,40 < d ≤ 3,60 | 1350 - 1560 | 1570 - 1760 | 1570 - 1760 | 1770 - 1970 | 1770 - 1970 | 40 | |||

| 3,60 < d ≤ 3,80 | 1340 - 1540 | 1550 - 1740 | 1550 - 1740 | 1750 - 1950 | 1750 - 1950 | 40 | |||

| 3,80 < d ≤ 4,00 | 1320 - 1520 | 1530 - 1730 | 1530 - 1730 | 1740 - 1930 | 1740 - 1930 | 35 | |||

| 4,00 < d ≤ 4,25 | 1310 - 1500 | 1510 - 1700 | 1510 - 1700 | 1710 - 1900 | 1710 - 1900 | 35 | |||

| 4,25 < d ≤ 4,50 | 1290 - 1490 | 1500 - 1680 | 1500 - 1680 | 1690 - 1880 | 1690 - 1880 | 35 | |||

| 4,50 < d ≤ 4,75 | 1270 - 1470 | 1480 - 1670 | 1480 - 1670 | 1680 - 1860 | 1680 - 1860 | 35 | |||

| 4,75 < d ≤ 5,00 | 1260 - 1450 | 1460 - 1650 | 1460 - 1650 | 1660 - 1840 | 1660 - 1840 | 35 | |||

| 5,00 < d ≤ 5,30 | 1240 - 1430 | 1440 - 1630 | 1440 - 1630 | 1640 - 1820 | 1640 - 1820 | 35 | |||

| 5,30 < d ≤ 5,60 | 1230 - 1420 | 1430 - 1610 | 1430 - 1610 | 1620 - 1800 | 1620 - 1800 | 35 | |||

| 5,60 < d ≤ 6,00 | 1210 - 1390 | 1400 - 1580 | 1400 - 1580 | 1590 - 1770 | 1590 - 1770 | 35 | |||

| 6,00 < d ≤ 6,30 | 1190 - 1380 | 1390 - 1560 | 1390 - 1560 | 1570 - 1750 | 1570 - 1750 | 35 | |||

| 6,30 < d ≤ 6,50 | 1180 - 1370 | 1380 - 1550 | 1380 - 1550 | 1560 - 1740 | 1560 - 1740 | 35 | |||

| 6,50 < d ≤ 7,00 | 1160 - 1340 | 1350 - 1530 | 1350 - 1530 | 1540 - 1710 | 1540 - 1710 | 35 | |||

| 7,00 < d ≤ 7,50 | 1140 - 1320 | 1330 - 1500 | 1330 - 1500 | 1510 - 1680 | 1510 - 1680 | 30 | |||

| 7,50 < d ≤ 8,00 | 1120 - 1300 | 1310 - 1480 | 1310 - 1480 | 1490 - 1660 | 1490 - 1660 | 30 | |||

| 8,00 < d ≤ 8,50 | 1110 - 1280 | 1290 - 1460 | 1290 - 1460 | 1470 - 1630 | 1470 - 1630 | 30 | |||

| 8,50 < d ≤ 9,00 | 1090 - 1260 | 1270 - 1440 | 1270 - 1440 | 1450 - 1610 | 1450 - 1610 | 30 | |||

| 9,00 < d ≤ 9,50 | 1070 - 1250 | 1260 - 1420 | 1260 - 1420 | 1430 - 1590 | 1430 - 1590 | 30 | |||

| 9,50 < d ≤ 10,00 | 1060 - 1230 | 1240 - 1400 | 1240 - 1400 | 1410 - 1570 | 1410 - 1570 | 30 | |||

| 10,00 < d ≤ 10,50 | - | 1220 - 1380 | 1220 - 1380 | 1390 - 1550 | 1390 - 1550 | 30 | |||

| 10,50 < d ≤ 11,00 | - | 1210 - 1370 | 1210 - 1370 | 1380 - 1530 | 1380 - 1530 | 30 | |||

| 11,00 < d ≤ 12,00 | - | 1180 - 1340 | 1180 - 1340 | 1350 - 1500 | 1350 - 1500 | 30 | |||

| 12,00 < d ≤ 12,50 | - | 1170 - 1320 | 1170 - 1320 | 1330 - 1480 | 1330 - 1480 | 28 | |||

| 12,50 < d ≤ 13,00 | - | 1160 - 1310 | 1160 - 1310 | 1320 - 1470 | 1320 - 1470 | 28 | |||

| 13,00 < d ≤ 14,00 | - | 1130 - 1280 | 1130 - 1280 | 1290 - 1440 | 1290 - 1440 | 28 | |||

| 14,00 < d ≤ 15,00 | - | 1160 - 1260 | 1160 - 1260 | 1270 - 1410 | 1270 - 1410 | 28 | |||

| 15,00 < d ≤ 16,00 | - | 1090 - 1230 | 1090 - 1230 | 1240 - 1390 | 1240 - 1390 | 28 | |||

| 16,00 < d ≤ 17,00 | - | 1070 - 1210 | 1070 - 1210 | 1220 - 1360 | 1220 - 1360 | 28 | |||

| 17,00 < d ≤ 18,00 | - | 1050 - 1190 | 1050 - 1190 | 1200 - 1340 | 1200 - 1340 | 28 | |||

| 18,00 < d ≤ 19,00 | - | 1030 - 1170 | 1030 - 1170 | 1180 - 1320 | 1180 - 1320 | 28 | |||

| 19,00 < d ≤ 20,00 | - | 1020 - 1150 | 1020 - 1150 | 1160 - 1300 | 1160 - 1300 | 28 | |||

| Wire with a size above 20mm diameter is used. Where such wire is specified the parties shall agree upon the properties and requirements at the time of enquiry and order. | |||||||||

|

Nominal Diameter mm |

SL, SM, SH |

DM, DH |

|

d<0,80 |

150 |

150 |

|

0,80≤d<1,60 |

120 |

100 |

|

1,60≤d |

120 |

70 |

|

The requirements apply unit packages the mass of which in kilograms does not exceed the value of 250×d (d = wire diameter in mm) or a value of 1000 kg; In the case of coils greater mass, appropriate agreements shall be made. |

||

|

Nominal Diameter mm |

Minimum Coating Mass1 g/m² |

||||||||

| 0,20 ≤ d < 0,25 | 20 | ||||||||

| 0,25 ≤ d < 0,40 | 25 | ||||||||

| 0,40 ≤ d < 0,50 | 30 | ||||||||

| 0,50 ≤ d < 0,60 | 35 | ||||||||

| 0,60 ≤ d < 0,70 | 40 | ||||||||

| 0,70 ≤ d < 0,80 | 45 | ||||||||

| 0,80 ≤ d < 0,90 | 50 | ||||||||

| 0,90 ≤ d < 1,00 | 55 | ||||||||

| 1,00 ≤ d < 1,20 | 60 | ||||||||

| 1,20 ≤ d < 1,40 | 65 | ||||||||

| 1,40 ≤ d < 1,65 | 70 | ||||||||

| 1,65 ≤ d < 1,85 | 75 | ||||||||

| 1,85 ≤ d < 2,15 | 80 | ||||||||

| 2,15 ≤ d < 2,50 | 85 | ||||||||

| 2,50 ≤ d < 2,80 | 95 | ||||||||

| 2,80 ≤ d < 3,20 | 100 | ||||||||

| 3,20 ≤ d < 3,80 | 105 | ||||||||

| 3,80 ≤ d ≤ 10,00 | 110 | ||||||||

|

1. The requirement for the zinc coating correspond to class C of EN 10244-2:2009; |

|||||||||

|

Nominal Size mm |

Permissible Deviations mm |

||||||||

| 0,20≤ d ≤ 0,25 | ±0,005 | ||||||||

| 0,25 < d ≤ 0,63 | ±0,008 | ||||||||

| 0,63 < d ≤ 0,75 | ±0,010 | ||||||||

| 0,75 < d ≤ 1,00 | ±0,015 | ||||||||

| 1,00 < d ≤ 1,20 | ±0,020 | ||||||||

| 1,20 < d ≤ 1,70 | ±0,020 | ||||||||

| 1,70 < d ≤ 2,60 | ±0,025 | ||||||||

| 2,60 < d ≤ 4,00 | ±0,030 | ||||||||

| 4,00 < d ≤ 5,30 | ±0,035 | ||||||||

| 5,30 < d ≤ 7,00 | ±0,040 | ||||||||

| 7,00 < d ≤ 9,00 | ±0,045 | ||||||||

| 9,00 < d ≤ 10,00 | ±0,050 | ||||||||

| 10,00 < d ≤ 11,00 | ±0,070 | ||||||||

| 11,00 < d ≤ 14,00 | ±0,080 | ||||||||

| 14,00 < d ≤ 18,00 | ±0,090 | ||||||||

| 18,00 < d ≤ 20,00 | ±0,100 | ||||||||

The difference between the maximum and the minimum diameter of the wire at the same cross section shall not be more than 50% of the total permissible deviation specified in the mechanical properties table.

If you have any question about the company's legal policy, copyright, trademark, other legal topics, or general product and service related queries, please fill in the form. We will reply you as soon as possible!